I remember asking the questions: Why is lead shot copper plated? Why is steel shot plated? And more recently why is bismuth and tungsten shot being plated? After years of wondering, I decided I wanted a better answer than I was finding in the marketing of most waterfowl and turkey hunting ammunition. So I began to study and I reached out to the owners of shotgun ammo manufacturing companies, professional metallurgists, and hunting ammo historians. More people answered my questions than I was expecting.

The first big question is why did they start copper plating shot? Well, long story short, about 100 years ago they were trying to find ways to keep lead shot from fusing together in high pressure loads. They eventually solved that problem with harder lead shot. But they noticed interesting performance benefits from the copper plating, so they continued doing it.

Plated Shot Improves Lubricity

The big thing that plated shot does is increase the lubricity of the shot. Just as it sounds, the platting acts as a lubricant on the shot. It lubricates the pellets against one another, against the barrel, against the air, and against the intended target.

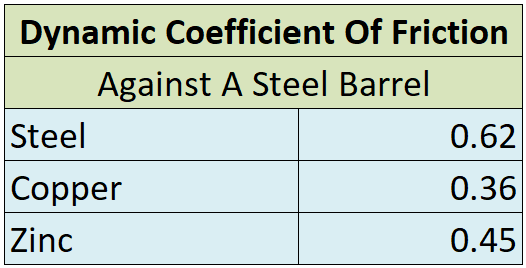

Most shotgun shot, whether it is steel, lead, bismuth, or tungsten is not polished to a perfect mirror finish. The plating ads that finish, thus reducing the friction of the pellets. But it does even more. Copper plating, along with zinc and others have a lower dynamic coefficient of friction than say steel does. So whether you are using steel shot or firing your shot through a steel barrel, or both, the plating cuts back on friction.

So what does that do? Why does it matter?

1) Sliding Through The Choke

Less friction and more lubricity means the pellets can smoothly slide against each other as they travel through the forcing cone, barrel, and most importantly the choke tube. The choke compresses the shot, elongating the shot column trying to tighten the pattern. If the choke is too tight or shot too rough, certain materials such as steel shot in particular will crunch together instead of sliding and elongating the shot column when compressed by the choke. The stored energy of being pushed together without sliding is then released and the pellets expand immediately after leaving the barrel which ruins the pattern. That has a significant effect in both tighter turkey hunting choke tubes and looser waterfowl chokes.

Adding copper platting, or to a lesser degree zinc or nickel lets the pellets slide against one another instead of smashing together. The result is denser patterns at essentially all ranges.

2) Sliding Through The Air

The second thing plating does, particularly that polished finish it gives, is aid the shot as it cuts through the air. Polished copper plating slices through the wind easier than rough lead, steel, or bismuth shot. Less aerodynamic friction means the shot loses velocity slower and has more range, less drop, and more energy on the target. Because of this it can hit harder than non-plated shot, especially compared to cheaper rougher finished shot.

The big thing to remember with this is that the effect is null at the muzzle. At 10 yards it is almost meaningless, but at 40 and 50+ yards is when it makes the most difference because the effect of wind and friction has had time to work, slowing down the un-plated shot more. The big question here is how much difference does this make? More about that momentarily.

3) Sliding Through The Target

Plating also helps the shot penetrate deeper into the intended target, whether you are hunting ducks, geese, turkeys, pheasants, or any other fowl. The decreased coefficient of friction from the plating, coupled with the benefits of the mirror finish, help it slide through tissue to go deeper. This also means the shot has more energy to break through bones when it reaches them.

These three factors combined result in higher pattern density, which means more pellets on the target. Each of those pellets arrives at the target with more velocity and slide through the birds a little more easily.

The Best Metals To Plate

Plating is most effective performance wise for lead shot and bismuth because they are softer materials which can deform on impact causing more trauma when they impact bone compared to steel which is more likely to ricochet. A slicker harder steel pellet is slightly more likely deflect off of bone rather than break through it.

Plating on steel started mostly for corrosion resistance. Tall pallets of steel ammo in hot damp warehouses for months and years on end too often resulted in rusty shot reaching the customers. Plating solved this problem very well. The marketing is spun to make it sound like it is helping the hunter, so their shot doesn’t rust in the field, but that is not very likely to happen in most scenarios, it helps the manufacture and distributors more.

Tungsten is sometimes copper plated as well, with the intension of improved pattern, velocity, and penetration performance.

Why Is Steel Shot Not Copper Plated?

Sometimes it is, but zinc and nickel plating are more cost effective for adhesion to steel in order to protect against moisture. So it is cheaper to not use copper on steel. Because of this, the effects of plating on steel in terms of patterning, velocity, and penetration are less pronounced than with lead or bismuth. However, there do seem to still be some gains for zinc and nickel-plated steel against un-plated steel. But the primary motivation for doing it is the corrosion resistance.

How Much Difference Does Plated Shot Make?

This was not an easy question to get experts to answer. Thankfully, it is something that I am able to test. After doing many ballistic gel and pattern tests myself, I am convinced there is a measurable difference.

I have found pattern density to improve by 10%-30% when testing plated vs. un-plated shot. However, there are a lot of variables here, and no company that I could find makes the same shell with the only difference between plated vs. un-plated shot. So, I would have to call these results anecdotal. But plated shot seems to come out on top with every test I’ve done to date. But keep in mind, these benefits pale in comparison to making sure you gun is properly fitted to you. A well fitted shotgun will be more accurate and outperform any gains you might see from plated shot. For more, I did a full article on the subject here: How To Fit A Shotgun To You.

When it comes to ballistics gel penetration, I have found that plated shot penetrates about 5-10% deeper than un-plated shot. This is a little bit more robust testing because there are fewer variables to control for. Plating and velocity are the main ones.

I was presented with documentation showing bismuth penetration and more importantly wound trauma has been seen to be 15%+ with copper plated shot vs non plated shot. I intend to test this personally in the near future and will update this article and do a video on the results.

Is Plated Shot Worth The Extra Expense?

The big question people ask next becomes: is plated shot worth the extra cost? After all my research, I would say “it depends”. The biggest benefits of copper plated shot or any plated shot are going to be potential increase in pattern density. If you try the copper plated shot with a few good choke tubes and it patterns better in your gun then it is absolutely worth it. If it patterns the same, I do not think the slight increase in terminal performance is worth the significant increase in cost.

What Are The Best Plated Shells?

I haven’t tested them all, but here are my favorite shells per category of all the ones I have tested.

- Zinc Plated Steel: Kent Fasteel

- Copper Plated Bismuth: BOSS Shotshells

- Copper Plated Lead: Winchester Long Beard XR

- Copper Plated Tungsten: BOSS Tom

Be sure to listen to The New Hunters Guide Podcast, and check us out on YouTube. If you want to learn more about hunting, check out the different hunting areas that my podcast covers, there are over 200 episodes, all organized by topic:

- First Steps

- Black Bear Hunting

- Crow Hunting

- Deer Hunting

- Dove Hunting

- Duck Hunting

- Goose Hunting

- Pheasant Hunting

- Predator Hunting

- Turkey Hunting

- Woodchuck Hunting

- General Tips and Gear

George Konetes Ph.D. – Founder and Host of the New Hunters Guide.

The New Hunters Guide is simply what George wishes he would have had when learning how to hunt; a single place to get practical hands on knowledge about different kinds of hunting, gear, strategy, and tips that can improve your comfort and fun factor in the woods.